Our vision for the future is to improve the quality of our products constantly.

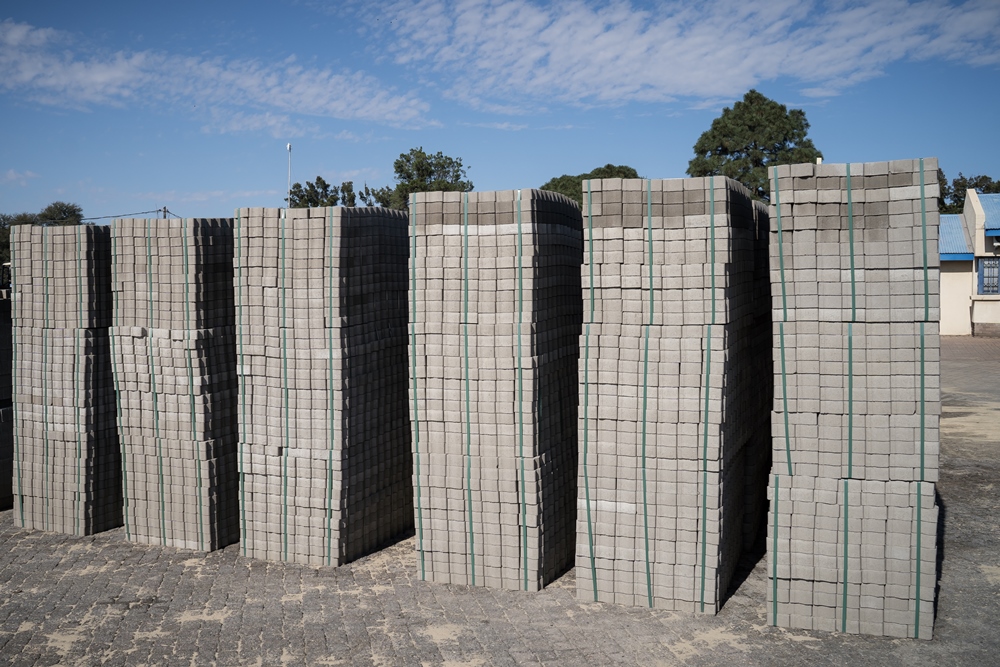

Our main products include cement bevel pavers, interlocking pavers, cement stock bricks, maxi stocks as well as cement hollow blocks.

Frequently Asked Questions

Megapascal (MPa) is a metric (SI) measurement unit of pressure. It refers to how much pressure a brick can withstand before it breaks.

Standard 25MPa/ECONO refers to bricks that adheres to previous SANS standards of 25MPa. The colours of each product on the Standard 25MPa/ECONO ranges are also lighter than their CMACS/SANS1058 approved counterparts.

This white haze is called efflorescence. Water reacts with cement inside bricks that produces water soluble calcium oxide. It is a natural phenomenon that appears randomly.

Click here to read more in depth about the topic.

Usually the rain washes it away in about 1 to 2 years. The quick solution is to wash the bricks with diluted hydrochloric acid (1 part hydrochloric acid, 20 parts water). WARNING- Washing with hydrochloric acid may change the brick shade and/or cause the surface of brick to become rougher.

Click here to read more in depth about the topic.

Yes, grey is the standard color but other colors are made on special orders

In 2012, the old compression test with a value of 25MPa was replaced with 3 new SANS/CMACS specifications. Firstly, the paving brick must be able to withstand a splitting force equal or greater than 2MPa. This test result is equivalent to a compression test with a value equal or greater than 30MPa. Secondly, the average water weight gain of the paving bricks must be 6.5% or less. Thirdly, the average mass loss of the paving bricks due to abrasion must be 15g or less.

Force is applied down the middle of the length of the brick. This is done to see how much force is necessary to split a paving brick into two. This test replaced the old compression test of 25MPa as a SANS/CMACS specification. A paving brick must be able to withstand a splitting force of 2MPa or more. This is equivalent to a minimum 30MPa result in a compression test.

This test is to determine if the paving bricks do not absorb too much water. Paving bricks are placed in a container of water for 24 hours. The paving bricks are then removed and weighed to see how much water was absorbed by the paving bricks. The average weight gain may not be more then 6.5% of the paving bricks original weight.

This test is to determine if the bricks can withstand a certain amount of abrasion. An example of abrasion is a truck tyre that turns on top of the paving bricks. Paving bricks are placed inside a tumbler with 600 steel ball bearings, for 60 minutes, rotating at a speed of 60rpm. The bricks are not allowed to lose more than 15g of its weight on average.

We would always advice contracting a paving specialist. For clients that wants to install the paving themselves, or supervise a contractor, we recommend the CMA illustrated guide to paving installation.

Complete our questionnaire to help determine the quality of the contractor you are going to use. You are able to compare the contractors to your disposal. Note that the higher the score, the higher the quality of the contractor, as well as the cost.

Click here to complete the questionnaire.

Download Manuals

Contact us

- 0169876100

- 0829048516

- sales@conframat.co.za

-

Vanderbijlpark Branch

42 Ravel Str

Plot 118, Zuurfontein

Vanderbijlpark

- 0169876125

- 0169876126

- 0796215969

- sales@conframat.co.za

-

Midvaal Branch

Cnr Graniet & Dolomiet Str

Pendale

Midvaal